Innovative Steel Production for Superior Quality Steel Melting Shop

HBI and/or DRI are combined with scrap in the Induction Furnace to ensure precise control over the steel chemistry.

The Steel Melting Shop (SMS) is equipped with an Induction Furnace, Ladle Refining Furnace (LRF), and Continuous Casting Machine (CCM).

HBI and/or DRI are melted in the Induction Furnace using electric current for efficient metal processing.

Once melting is complete, the liquid metal is tapped and transferred to the LRF for secondary refining, including Argon Oxygen Decarburization (AOD).

In the LRF and AOD, deoxidizers and alloys are added, removing oxygen, sulfur, and phosphorus to achieve the desired steel chemistry.

Inert Argon gas is used to purge the liquid steel, ensuring it is ultra-clean and homogenized for superior quality.

After processing in the LRF, the liquid steel is cast into billets in the CCM, ready for further processing into rebar.

Induction Furnace

- 25 Ton Induction Furnace

- Transformer capacity – 25 MVA

- Hydraulic Tapping Mechanism

- Temperature measurement & sampling

Ladle Refining Furnace

- 30 MT capacity

- Transformer capacity – 6.5 MVA

- Continuous argon purging system

- Wire feeding capability

AOD

- Decarburization.

- This process is the air–oxygen– inert gas decarburization (AOD) process, for making stainless steel out of mild steel, mild steel out of high cast-iron melt, and alloy steel economically.

- PLC-based gas mixing station of MRK gives flow measurements compensated for pressure and temperature variation. This avoids, “over oxidation” of liquid metal.

CCM

- 24 Ton/Hour/Strand

- Casting Speed 3.8 Min at 110SQ

- Twin Caster

- 130×130 mm

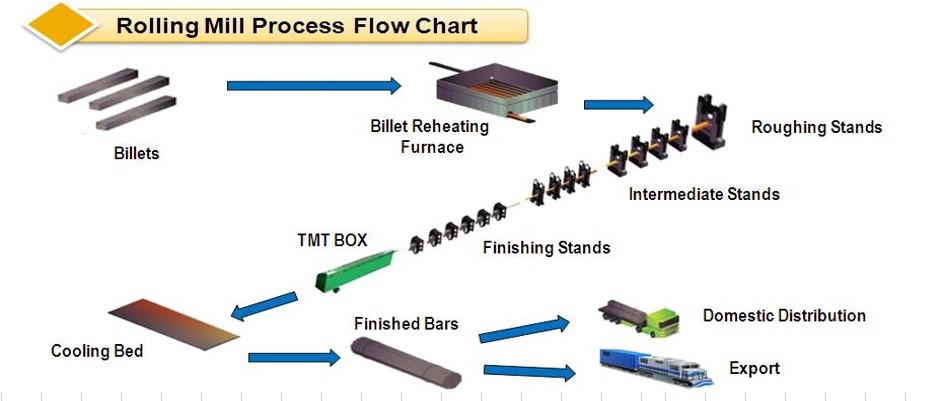

Transforming Billets into High-Quality Rebar Rolling Mill

- Billets are reheated in a gas fired pusher type furnace for heating, soaking and feeding to rolling stands to produce rebar.

- Reinforcement bars are produced through fully automated rolling mill.

- Capable of rolling full size range of reinforcing bars as per customer needs

- For detailed size and grade/class please go through “GTB Steel PRODUCT CATALOGUE”.

- Advanced bar counting & tying system ensuring same number of bars in each bundle for a particular size and bundle weight.

- Due to very high quality billets and state of the art German technology rolling mill with thermex “QST” ( QUENCHING & SELF TEMPERED ) process, all

chemical, mechanical & metallurgical properties are guaranteed.